Common Troubleshooting

Suitable for ultra-small series Switching actuators

This wizard applies to the DCL ultra-small series of actuators with the following model numbers:

- DCL-02

1、Common malfunctions and troubleshooting methods.

| fault | Possible reasons | Exclusion method |

|---|---|---|

| The actuator will not open or close during initial startup | 1. Incorrect wiring | Check if the wiring is correct according to the wiring diagram of the actuator? |

| 2. Incorrect power supply | Confirm that the output voltage of the power supply is ± 10% of the rated voltage of the actuator, and the output current is 3 times the rated current of the actuator. | |

| 3. Abnormal control switch or control relay | Measure the input voltage of the actuator switch control terminal with a multimeter to confirm if it meets expectations? | |

| 4. Matching problem with control system | Measure the function of the actuator using a mechanical switch. If the actuator is running normally, check if the output logic of the control system meets expectations? | |

| 5. Multiple actuators or actuators connected in parallel with other devices | The switch type actuator is started through a starting capacitor, and parallel connection with other devices will affect the capacitance value of the starting capacitor. So, switch type actuators can only use single channel control and cannot be connected in parallel. | |

| The actuator can only be turned on or off | 1. Incorrect wiring | 1. Use a mechanical switch to measure the function of the actuator. If the actuator is running normally, check if the output logic of the control system meets expectations? |

| 2. Improper setting of fully open/fully closed cam | Refer to"How to set switch type electric valve"to correctly set the cam position. | |

| The actuator stops in the middle of the stroke | 1. Valve stuck | Check for valve sticking, eliminate sticking, and retry after actuator overload protection cooling. |

| 2. Potential solid substances in the fluid medium can cause valve jamming. | Check if there is any solid object stuck in the valve in the fluid medium, eliminate the valve stuck, and retry after the actuator overload protection has cooled down. | |

| 3. Improper setting of fully open/fully closed gear block | Refer to"How to set switch type electric valve"and correctly set the stop position. | |

| Using the handle, the actuator cannot be rotated | Potential solid substances in the fluid medium can cause valve jamming. | Check if there is any solid object stuck in the valve in the fluid medium, eliminate the valve stuck, and retry after the actuator overload protection has cooled down. |

| 2. Valve stuck | Check for valve sticking, eliminate sticking, and retry after actuator overload protection cooling. | |

| 3. The actuator deceleration mechanism is damaged. | Remove the actuator from the valve and turn the handle. If it cannot rotate, replace it with a new actuator. | |

| Position feedback signal has no output | 1. Incorrect switch wiring | Check if the wiring is correct according to the wiring diagram of the actuator? |

| 2. Improper setting of fully open/fully closed cam | Refer to"How to set switch type electric valve"to correctly set the cam position. | |

| 3. Overcurrent causes damage to the position feedback signal switch. | 1. Refer to"How to set up a switch type electric valve", check if the fully open/fully closed cam presses the position feedback switch? |

2、Please check that the application conditions are in accordance with the parameters.

Electric actuators can fail due to improper use or under the wrong application conditions. Long-term trouble-free operation of the actuator will be ensured under the application conditions defined in the product specification.

- Supply voltage:The voltage of the power supply must be within the rated operating voltage of the actuator. Overvoltage or undervoltage may result in reduced actuator life.

- Supply current:Since the starting current of the motor is much larger than the rated current. To ensure reliable operation of the actuator, use a power supply with an output current capacity more than three times the rated current of the actuator.

- Temperature:Ensure that the actuator operates within the rated operating temperature range. Use of the actuator in environments outside of the rated operating temperature range may result in malfunction or reduced service life of the actuator, and ultimately, failure of the actuator.

- Environment:DCL开关型执行机构具有IP67防风雨等级。一般适用于室内或室外应用。提供一定程度的防雨、防溅水。保护执行器免受雨淋,雪、冰和紫外线(阳光)Typically extends the life of the product. Very corrosive environments may cause premature failure of electronic equipment. Do not use non-explosion-proof series actuators in explosion-proof environments.

- Energized persistence rate:DCL开关型执行器的通电持续率为70%(每分钟运行42秒,必须关闭18秒),超过70%of the energization duration rate will cause the motor to go into overheat protection.

3、Check that the actuator is wired correctly

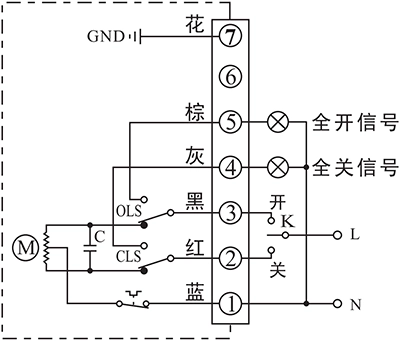

A型:带极限位置开关(有源触点)

通过开关电路实现“开”、“关”operation, and outputs a set of fully open and fully closed active signals.

Wiring Instructions:

1、 端子1接电源中线;

2、 电源相线与端子2接通时为“关”运行;

3、 电源相线与端子3接通时为“开”运行;

4、 电源相线与端子2接通且“关”运行到位时, 端子4所接“全关信号“指示灯亮;

5、 电源相线与端子3接通且“开”运行到位时, 端子5所接“全开信号“指示灯亮;

6、 Terminal 7 ground wire.

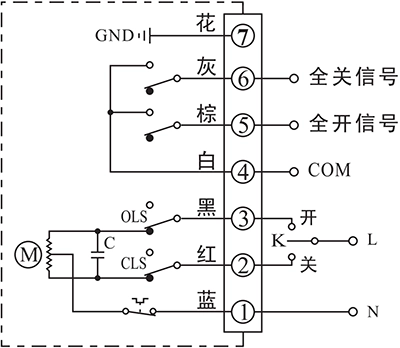

B型:带中间位置开关(无源触点)

通过开关电路实现“开”、“关”operation, and outputs a set of fully open and fully closed passive signals.

Wiring Instructions:

1、 端子1接电源中线;

2、 电源相线与端子2接通时为“关”运行;

3、 电源相线与端子3接通时为“开”运行;

4、 端子4为无源触点公共端;

5、 “开”运行到位时,端子5输出“全开信号”;

6、 “关”运行到位时,端子編出“全关信号“ ;

7、 Terminal 7 ground wire.

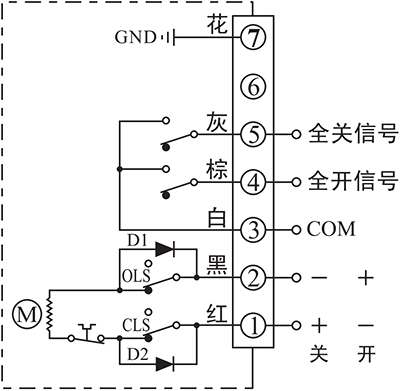

GType: DC control circuit with passive contact switches

根据二极管的单向 导电性,通过对直流电源正负极换向, 实现“开”、“关” Operates and outputs a set of fully open and fully closed passive signals.

Wiring Instructions:

1、 端子1接电源正极,端子2接电源负极时为 “关”运行;柠2接电源正极,够 1接 电源负极时为“开”运行;

2、 端子3为无源触点公共端;

3、 “开”运行到位时,端子确出“全开信号”;

4、 “关”运行到位时,端子5输出“全关信号”;

5、 Terminal 7 ground wire.