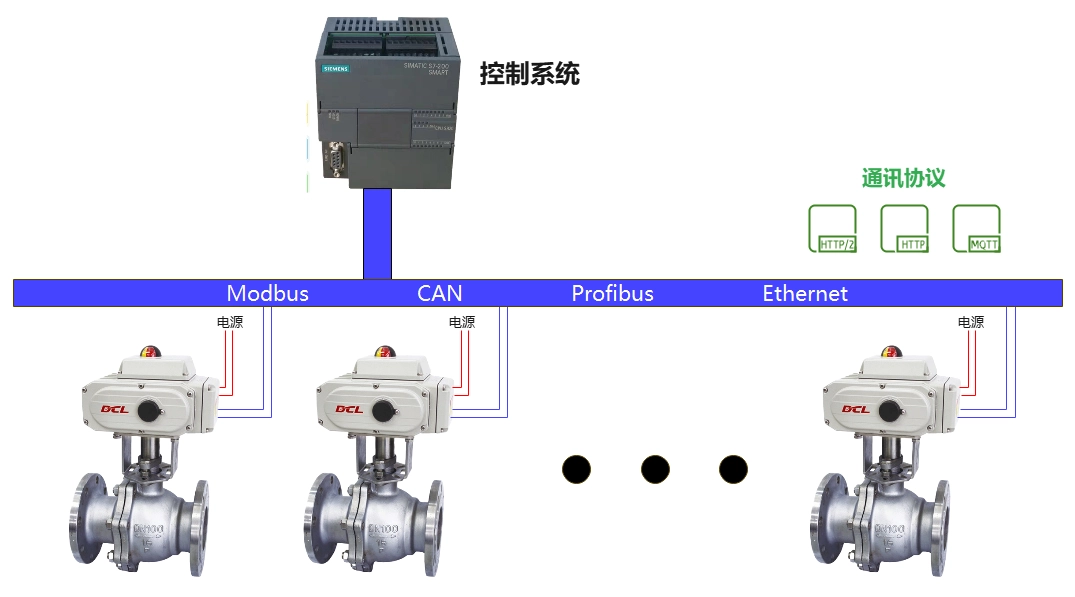

The DCL series actuators support the Modbus-RTU protocol. By referring to this application manual, you can connect the DCL actuator to Modbus.

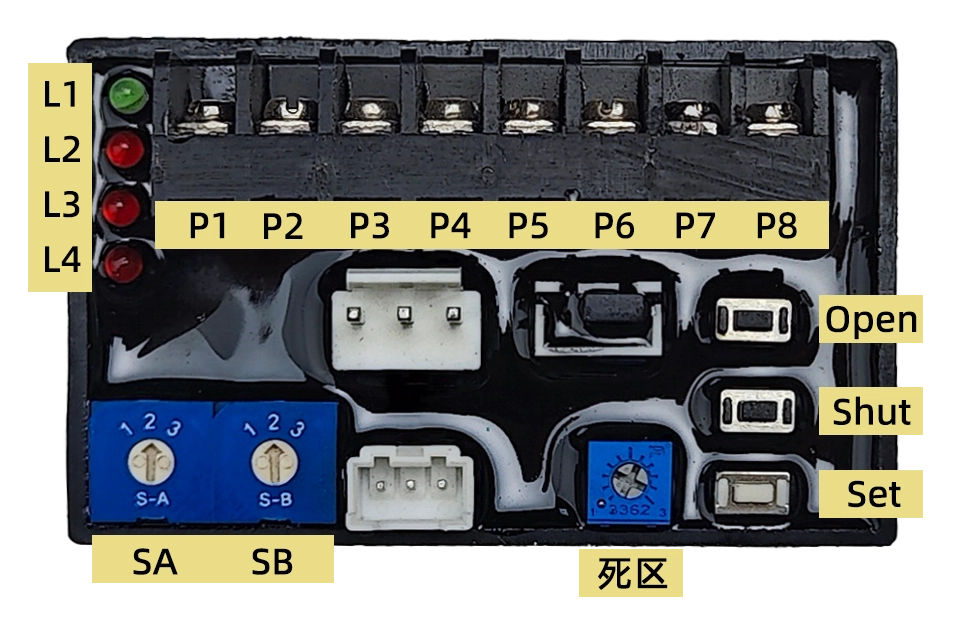

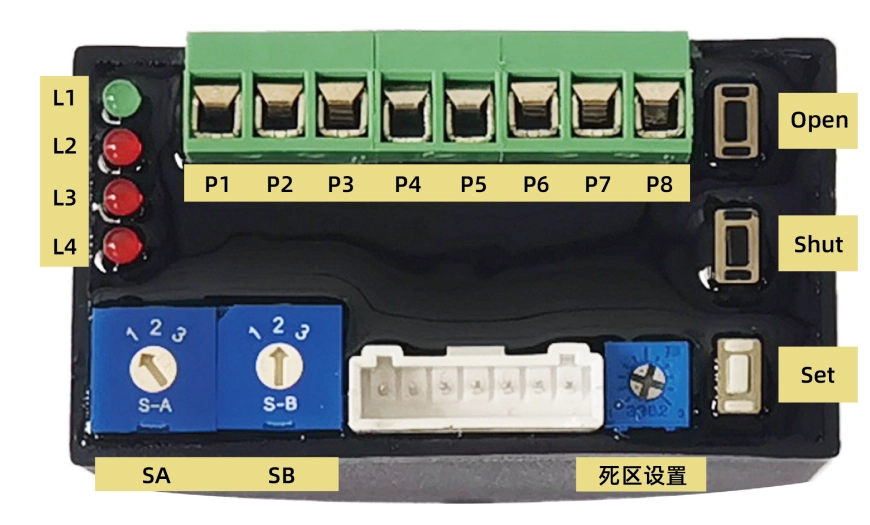

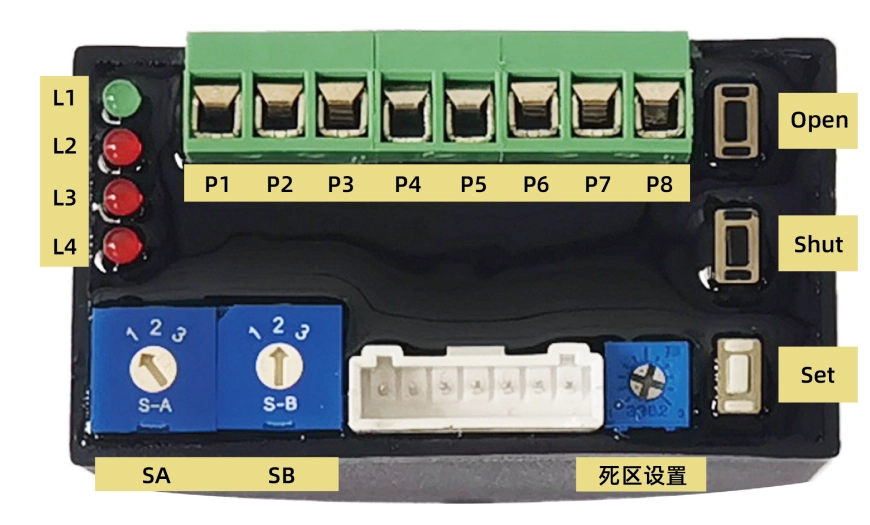

Description du panel

1. Définition de l'interface

P1: 220VAC Neutral (N)

P2: 220VAC Live (L)

P3: 4-20mA Input –

P4: 4-20mA Input +

P5: 4-20mA Output –

P6: 4-20mA Output +

P7: RS485 A

P8: RS485 B

2. Buttons

Ouvert : In “Setup Mode” (when switch SA points to “2”), pressing this key opens the actuator, and releasing it stops the motor. Pressing Fixer et Ouvrir simultaneously is used for full-open position calibration.

Navette : In “Setup Mode,” pressing this key closes the actuator, and releasing it stops the motor. Pressing Fixer et Nulle part ailleurs simultaneously is used for full-close position calibration.

Ensemble : Used in combination with Ouvrir et Nulle part ailleurs in “Setup Mode” to perform specific functions.

3. Selector Switch

SA : Selects the input signal’s direct/reverse action mode and setup state. It must be set while powered on for it to be effective. Factory default is 1:

1 – Direct Action

2 – Setup Mode

3 – Reverse Action

SB : Sets the safety position. When an external control signal is lost, the actuator moves to the specified position. Factory default is 2:

1 – Move to Full Open

2 – Hold Current Position

3 – Move to Full Close

Remarque : When using Modbus control, SB must be set to position 2.

4. Deadband Value Adjustment Potentiometer

Adjusts the deadband value. Turning clockwise increases the deadband; counterclockwise decreases it. The range is 0.5% – 5.0% (factory default is 1.5%).

5. Indicator Lights

L1 (vert) : Power Indicator – Lights up when power is supplied.

L2 (rouge) : Input Signal Failure Indicator – Lights up when input signal fails.

L3 (rouge) : Position Detection Failure Indicator – Lights up if the position potentiometer is open, shorted, or damaged.

L4 (rouge) : Jamming Failure Indicator – Lights up when jamming occurs.

Paramètres

To enter “Setup Mode,” set SA pour positionner 2. This mode allows for:

Étalonnage des déplacements

Input signal failure handling

Deadband value adjustment

Manual operation

Calibrage du courant de sortie

1. Setting End-position

Setting End-position of Close: Adjust the valve to the end-position of close using Ouvrir and/or Nulle part ailleurs buttons. Press Fixer, then Nulle part ailleurs, and hold both for about 4 secondes jusqu'à L2 lights up, then release both buttons. L2 turns off, indicating setting completion.

Setting End-position of Open: Adjust the valve to the end-position of open using Ouvrir and/or Nulle part ailleurs buttons. Press Fixer, then Ouvrir, and hold both for about 4 secondes jusqu'à L2 lights up, then release both buttons. L2 turns off, indicating setting completion.

2. Setting Modbus Address

The Modbus communication address and baud rate can be modified via Modbus commands.

Factory default address: 1

Factory default baud rate: 9600

3. Deadband Value Adjustment

Turning the potentiometer clockwise increases the deadband.

Turning it counterclockwise decreases the deadband.

Each tick mark corresponds to a 0.5% change.

If set below 0.5%, it is automatically processed as 0.5%.

En Setup Mode, use Ouvrir ou Nulle part ailleurs to manually open or close the valve.

Operation

To start automatic operation, set SA pour positionner 1 ou 3.

Upon power-up, the actuator defaults to 4-20mA signal control.

Sending a Modbus command switches the actuator to communication control mode.

After power cycling, the actuator returns to analog control mode.

Important: When using Modbus control:

Ensure SB is set to position 2.

Every control command must include the control mode and position value to prevent unintended actions after a restart.

Using 4-20mA for Position Control

| Signal d'entrée | 4mA | 8mA | 12mA | 16mA | 20mA |

|---|---|---|---|---|---|

| Pointer Position | FERMER (0) | 2.5 | 5 | 7.5 | OPEN (100) |

| Valve Opening (%) | 0% | 25% | 50% | 75% | 100% |

| Signal de sortie | 4mA | 8mA | 12mA | 16mA | 20mA |

Remarque :

En reverse action mode, 4mA corresponds to 100% openet 20mA corresponds to 0% open.

Servo controller accuracy level: ±1%

Hysteresis: <1%

Using Modbus to Control Actuator Position

Physical Layer

The DCL actuator supports the Modbus-RTU protocol and uses the RS485 interface at the physical layer.

Communication Address: Configurable from 1 to 127, default is 1.

Baud Rate: Configurable, default is 115200.

Serial Port Format: 1 start bit + 8 data bits + 1 stop bit.

Broadcast Functionality: Supported.

Interface Definition

| Pin | Function |

|---|---|

| P1 | Power (-) |

| P2 | Power (+) |

| P7 | RS485 A |

| P8 | RS485 B |

| P3~P6 | Reserved for analog signals (4 |

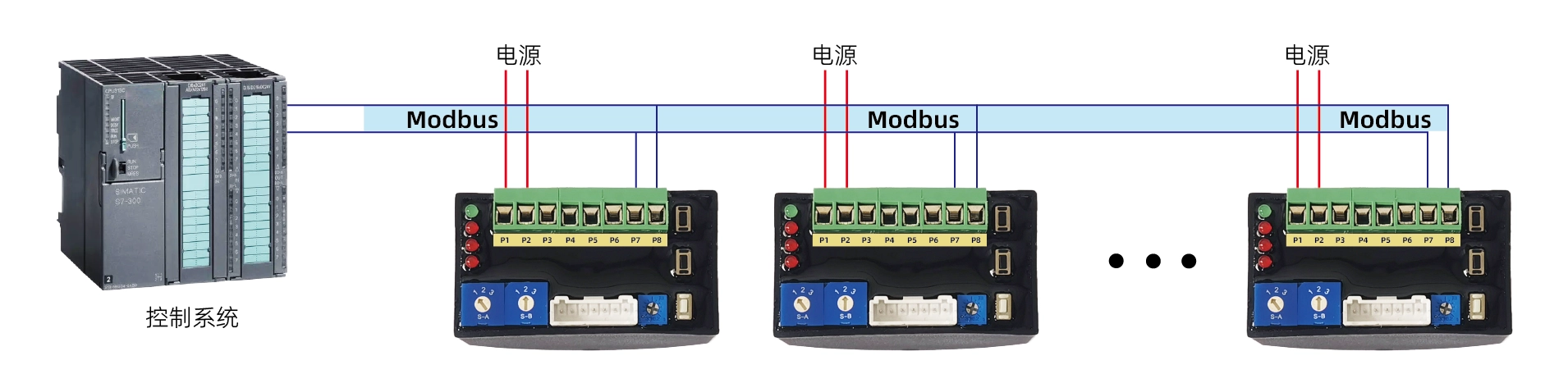

Modbus Wiring Diagram

Couche application

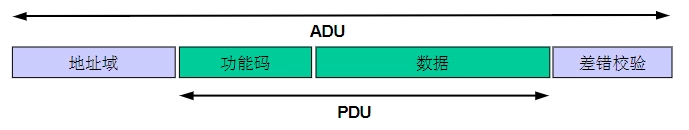

1. ADU (Application Data Unit)

2. Codes de fonction

| ID | Nom | Description |

|---|---|---|

| 0x03 | Read Multiple Registers | Reads a block of holding registers from a remote device. |

| 0x06 | Write Single Register | Writes a single register on a remote device. |

| 0x10 | Write Multiple Registers | Writes a block of consecutive registers (1 to approximately 120 registers). |

3. Configuring Communication Parameters

Registers 0x0040 – 0x0042 are used for communication settings:

Write 0xA501 to register 0x0040 pour entrer configuration mode.

Modify register 0x0041 (communication address) and register 0x0042 (baud rate).

The new parameters take effect within 1 second, and further communication must use the updated settings.

Exit configuration mode by writing 0x0000 à register 0x0040.

4. Forcing Default Communication Mode

Fixer SA à position 2 et SB à position 2.

Appuyer et maintenir la touche KS button for about 3 seconds jusqu'à ce que le red light blinks, then release the button.

Appuyer et maintenir la touche KC button for about 3 seconds jusqu'à ce que le red light stays on, then release the button.

The communication parameters are now reset to default values.

Fixer SA back to position 1 to exit this mode.

The new settings remain even after restarting the device.

Remarque :

If you forget the previous communication parameters, use this method to restore the default communication mode and configure the communication settings again.

Register List

| Register Address | Bits | Group | Signal Name | Min Value | Max Value | Unit | R/W | Type | Description |

|---|---|---|---|---|---|---|---|---|---|

| 0x0010 | b15-b5 | – | – | – | – | – | r/w | hexagone | Reserved (0) |

| b4 | contrôle | Arrêter | – | – | – | – | r/w | hexagone | 1: Stop, 0: Normal operation |

| b1-b0 | contrôle | Mode | – | – | – | – | r/w | hexagone | 1: Communication control, others: Exit communication control |

| 0x0011 | b15-b0 | contrôle | SetOpenDegree | 0 | 10000 | % | r/w | int/hex | 0-10000 corresponds to 0-100% valve opening (scaling factor: 1/100) |

| 0x0018 | b15-b6 | – | – | – | – | – | r | hexagone | Reserved (0) |

| b5 | info | errPosition | – | – | – | – | r | hexagone | 1: Position signal failure |

| b4 | info | errSignal | – | – | – | – | r | hexagone | 1: Input signal failure |

| b3 | info | overTorqueFlag | – | – | – | – | r | hexagone | 1: Overload detected |

| b2 | info | drapeau coincé | – | – | – | – | r | hexagone | 1: Jamming detected |

| b1 | info | openRunFlag | – | – | – | – | r | hexagone | 1: Opening valve |

| b0 | info | closeRunFlag | – | – | – | – | r | hexagone | 1: Closing valve |

| 0x0019 | b15-b0 | info | diplôme ouvert | 0 | 10000 | % | r | int/hex | 0-10000 corresponds to 0-100% valve opening (scaling factor: 1/100) |

| 0x0040 | b15-b0 | config | cfgMode | 1 | 127 | – | rw | hexagone | 0x0000: Normal mode, 0xA501: Configuration mode |

| 0x0041 | b15-b0 | config | cmm_addr | 1 | 127 | – | rw | hexagone | Sets communication address |

| 0x0042 | b15-b0 | config | cmm_baudrate | – | – | – | rw | hexagone | 0: 4800 baud, 1: 9600 baud, 2: 19200 baud, 3: 115200 baud |

Communication Command Examples

1. Control Valve Position

Entering Communication Control Mode:

Send → ◇01 10 00 10 00 01 02 00 01 65 00

Receive ← ◆01 10 00 10 00 01 00 0C

Setting Valve Position: 0%

Send → ◇01 10 00 11 00 01 02 00 00 A5 11

Receive ← ◆01 10 00 11 00 01 51 CC

Setting Valve Position: 50% (5000 → 0x1388)

Send → ◇01 10 00 11 00 01 02 13 88 A8 47

Receive ← ◆01 10 00 11 00 01 51 CC

Setting Valve Position: 100% (10000 → 0x2710)

Send → ◇01 10 00 11 00 01 02 27 10 BF 2D

Receive ← ◆01 10 00 11 00 01 51 CC

Stopping Operation

Send → ◇01 10 00 10 00 01 02 00 11 64 CC

Receive ← ◆01 10 00 10 00 01 00 0C

2. Read Valve Status

Send → ◇01 03 00 18 00 02 44 0C

Receive ← ◆01 03 04 00 30 00 00 FA 3C

3. Set Communication Address

Entering Configuration Mode:

Send → ◇01 10 00 40 00 01 02 A5 01 12 00

Receive ← ◆01 10 00 40 00 01 00 1D

Change Communication Address to: 2

Send → ◇01 10 00 41 00 01 02 00 02 28 80

Receive ← ◆01 10 00 41 00 01 51 DD

Exit Configuration Mode:

Send → ◇02 10 00 40 00 01 02 A5 00 C7 30

Receive ← ◆02 10 00 40 00 01 00 2E

4. Set Communication Baud Rate

Entering Configuration Mode:

Send → ◇01 10 00 40 00 01 02 A5 01 12 00

Receive ← ◆01 10 00 40 00 01 00 1D

Change Baud Rate to: 9600

Send → ◇01 10 00 42 00 01 02 00 01 68 B2

Receive ← ◆01 10 00 42 00 01 A1 DD

Exit Configuration Mode:

Send → ◇01 10 00 40 00 01 02 A5 00 D3 C0

Receive ← ◆01 10 00 40 00 01 00 1D