This guide is applicable to the DCL Ultra-Small Series actuators, with the following models:

DCL-02A

DCL-02B

DCL-02G

Common Faults and Troubleshooting Methods

| Fault | Possible Causes | Troubleshooting Methods |

|---|---|---|

| Actuator does not open or close on initial start | 1. Incorrect wiring | Check the wiring according to the actuator’s wiring diagram. |

| 2. Incorrect power supply | Ensure the power supply voltage is within ±10% of the actuator’s rated voltage and the current is 3 times the rated current. | |

| 3. Faulty control switch or relay | Measure the input voltage at the actuator’s control terminal using a multimeter to verify it matches expectations. | |

| 4. Control system mismatch | Test the actuator with a mechanical switch. If it operates normally, verify the control system’s output logic. | |

| 5. Multiple actuators or actuators and other devices connected in parallel | Switch actuators should use single-path control and not be wired in parallel, as this affects the startup capacitor. | |

| Actuator can only open or close | 1. Incorrect wiring | Check the wiring using the actuator’s wiring diagram. |

| 2. Incorrect full open/close cam setting | Refer to the “How to Set Electric Switch-Type Valves” guide and correctly set the cam positions. | |

| Actuator stops in the middle of travel | 1. Valve jammed | Check for blockages in the valve. Clear any obstruction and retry after the actuator’s overload protection cools. |

| 2. Solid material in fluid causing valve jam | Inspect the fluid for solid particles causing valve jams. Clear the jam and retry after the actuator’s overload protection cools. | |

| 3. Incorrect full open/close stopper setting | Refer to the “How to Set Electric Switch-Type Valves” guide and correctly adjust the stopper positions. | |

| Unable to turn actuator using the handle | 1. Solid material in fluid causing valve to seize | Check for blockage in the valve. Clear the blockage and retry after the actuator’s overload protection cools. |

| 2. Valve seizing | Inspect the valve for jamming. Clear the blockage and retry after the actuator’s overload protection cools. | |

| 3. Damaged actuator reduction mechanism | Remove the actuator from the valve and rotate the handle. If it doesn’t move, replace the actuator. | |

| No position feedback signal | 1. Incorrect wiring at the switch | Check the wiring according to the actuator’s wiring diagram. |

| 2. Incorrect full open/close cam setting | Refer to the “How to Set Electric Switch-Type Valves” guide and set the cam position correctly. | |

| 3. Overcurrent causing position feedback switch damage | 1. Check if the full open/close cam is pressing on the position feedback switch correctly, as per the guide. | |

| 2. Measure if the position feedback circuit is closed. |

Verify that the operating conditions meet the parameter requirements.

Electric actuators may fail due to improper use or being used in incorrect operating conditions. When used within the operating conditions defined in the product specifications, the actuator can be expected to operate reliably for an extended period without failure.

Supply Voltage: The voltage from the power supply must be within the rated operating voltage range of the actuator. Overvoltage or undervoltage may shorten the actuator’s lifespan.

Supply Current: The starting current of the motor is significantly higher than the rated current. To ensure reliable operation, use a power supply capable of delivering at least 3 times the rated current of the actuator.

Temperature: Ensure the actuator operates within its rated temperature range. Using the actuator outside this range may result in poor performance, reduced lifespan, and eventual failure.

Environment: The DCL switch-type actuator has an IP67 weatherproof rating, making it suitable for both indoor and outdoor applications. It offers a degree of protection against rain and splashing water, helping to prolong the actuator’s life by shielding it from rain, snow, ice, and UV (sunlight). However, in highly corrosive environments, electronic components may fail prematurely. Non-explosion-proof actuators should not be used in explosive environments.

Duty Cycle: The DCL switch-type actuator has a duty cycle of 70% (42 seconds of operation per minute, followed by 18 seconds of rest). Exceeding this duty cycle may cause the motor to enter thermal protection.

Check the Wiring of the Actuator

Ensure the actuator is wired correctly according to the wiring diagram provided by the manufacturer. Follow these steps to verify the wiring:

Power Supply:

Check the power supply connections to ensure they match the actuator’s required input voltage and current.

Control Connections:

Verify that the input and output control connections are securely attached and in the correct configuration as per the actuator’s wiring diagram.

Signal Wiring:

Check the wiring for control signals, such as 4-20mA or 0-10V, depending on the actuator’s specifications.

Confirm that there are no loose connections or short circuits.

Grounding:

Ensure that the actuator is properly grounded to prevent electrical interference or damage.

Connections to Other Equipment:

If the actuator is connected to other devices, make sure those connections are also correct and do not cause interference or power issues.

If the wiring appears correct, but the actuator is still malfunctioning, further troubleshooting or assistance from a technician may be necessary.

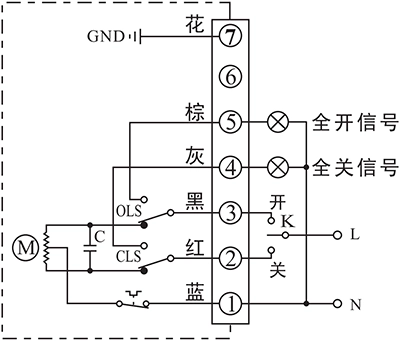

A - Con 2 salidas de señal de posición final activas

- Actuador de control para abrir o cerrar con K

- El terminal de salida de posición final ABIERTO/CERRADO enviará el evento como una forma de señal activa de 220VAC cuando se alcance la posición final.

Detalles de conexión:

- Conectar el neutro de alimentación AC85-220V a P1.

- Conmutar la línea AC85-220V a CLOSE(P2) para cerrar la válvula.

- Conmute la línea AC85-220V a OPEN(P3) para abrir la válvula.

- P5 es el terminal de posición final ABIERTO que dará salida a una fuente AC220V que puede ser usada para conducir una luz de indicación cuando el actuador alcance la posición final de abierto.

- P6 es la posición final del terminal ABIERTO que dará salida a una fuente AC220V que puede ser utilizada para conducir una luz de indicación cuando el actuador alcanza la posición final de cierre.

- Conecte la masa a P7.

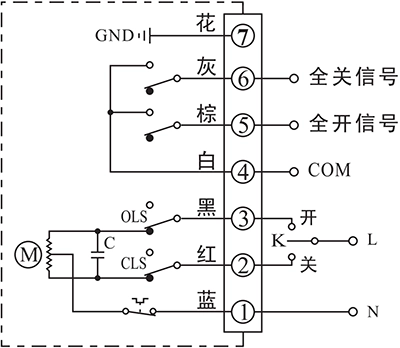

B - With 2 passive end-position switche

- Actuador de control para abrir o cerrar con K

- El terminal de salida de posición final ABRIR/CERRAR enviará el evento en forma de señal pasiva cuando se alcance la posición final.

Detalles de conexión:

- Conectar el neutro de alimentación AC85-220V a P1.

- Conmutar la línea AC85-220V a CLOSE(P2) para cerrar la válvula.

- Conmute la línea AC85-220V a OPEN(P3) para abrir la válvula.

- P4 es la COM para la señal de contacto pasivo de posición final ABIERTO/CERRADO que normalmente está conectada a la señal GND.

- P5 es el terminal de posición final ABIERTO que se conectará a COM cuando el actuador alcance la posición final de abierto.

- P6 es el terminal de posición final CERRADO que se conectará a COM cuando el actuador alcance la posición final de cerrado.

- Conecte la masa a P7.

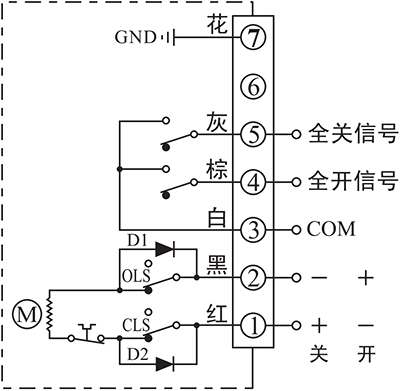

G - Motor de corriente continua con 2 interruptores de posición final

- Actuador de control para abrir o cerrar por la dirección de alimentación entre el terminal 1 y 2

- El terminal de salida de posición final ABRIR/CERRAR enviará el evento en forma de señal pasiva cuando se alcance la posición final.

Detalles de conexión:

- Conectar DC24V+ a P1 y DC24V- a P2 para cerrar la válvula.

- Conectar DC24V+ a P2 y DC24V- a P1 para cerrar la válvula.

- P3 es la COM para la señal de contacto pasivo de posición final ABIERTO/CERRADO que normalmente está conectada a la señal GND.

- P4 es el terminal de posición final ABIERTO que se conectará a COM cuando el actuador alcance la posición final de abierto.

- P5 es el terminal de posición final CERRADO que se conectará a COM cuando el actuador alcance la posición final de cerrado.

- Conecte la masa a P7.

Nota:

- El circuito dentro del recuadro discontinuo es el circuito interno del actuador. Mientras que el circuito exterior es una demostración de la conexión eléctrica para el uso del actuador.

- Si tiene otros requisitos específicos sobre el circuito de conexión, no dude en ponerse en contacto con nuestro servicio de asistencia técnica.

When conducting troubleshooting on-site, feel free to contact our technical service personnel immediately for assistance in diagnosing and resolving the issue.

Contact phone number: 13026331611 (Mr. Chen)

鄂公网安备 42018502006527号

鄂公网安备 42018502006527号