1. What is an Explosion?

An explosion occurs when flammable substances mix with oxygen and ignite under certain conditions. If the reaction speed exceeds the speed of sound, it results in a destructive explosion wave.

2. What is Explosion Protection?

To prevent explosions, at least one of the three key factors must be controlled:

Flammable substances

Oxygen

Ignition source

Since flammable substances and oxygen are often unavoidable in industrial environments, the ignition source must be controlled.

Electrical equipment is a potential ignition source due to:

✔ Surface heating during operation

✔ Electrostatic discharge

✔ Sparks from electrical currents

Explosion-proof electrical equipment is designed to prevent excessive surface temperatures and electrical sparks, ensuring that it does not become an ignition source.

3. Classification of Hazardous Environments

Explosion-proof electrical equipment is classified into two categories:

Category I: Equipment for coal mines

Category II: Equipment for other explosive gas environments

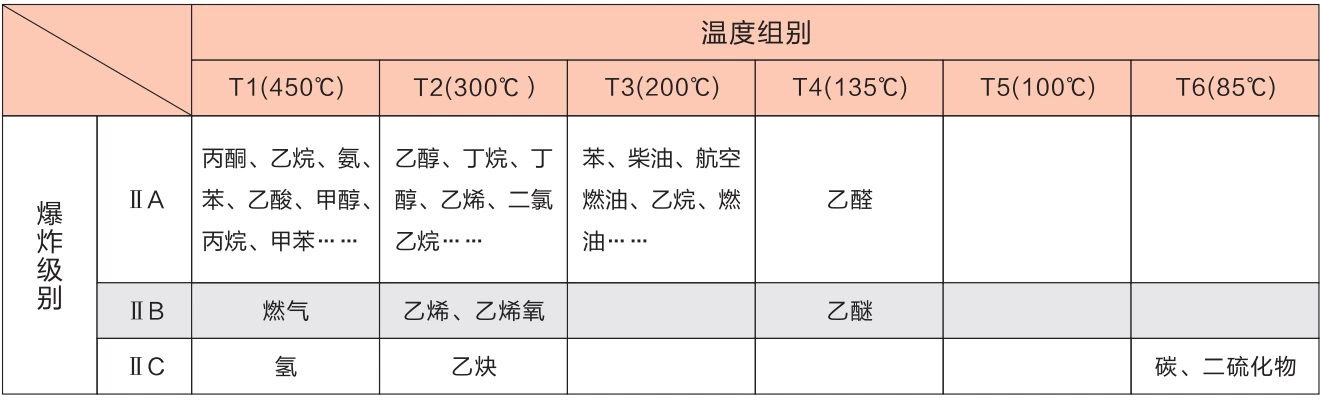

Category II Equipment

Explosion Groups (Based on Safety Gap & Ignition Current)

IIA

IIB (can be used in IIA conditions)

IIC (can be used in IIA & IIB conditions)

Temperature Groups (Based on Maximum Surface Temperature)

T1 (450°C)

T2 (300°C)

T3 (200°C)

T4 (135°C)

T5 (100°C)

T6 (85°C)

More than 90% of explosive gases fall under IIA, IIB groups and T1–T4 temperature classifications.

4. How is Explosion Protection Achieved?

Several methods ensure that electrical equipment is safe for explosive environments, as defined by GB3836, IEC60079, EN50014 standards.

Explosion-Proof (Exd) Design

DCL explosion-proof actuators are manufactured in accordance with:

✔ GB3836.1-2010, GB3836.2-2010

✔ IEC 60079-0, IEC 60079-1, IEC 60079-31

✔ ISO/IEC 80079-36, ISO/IEC 80079-37

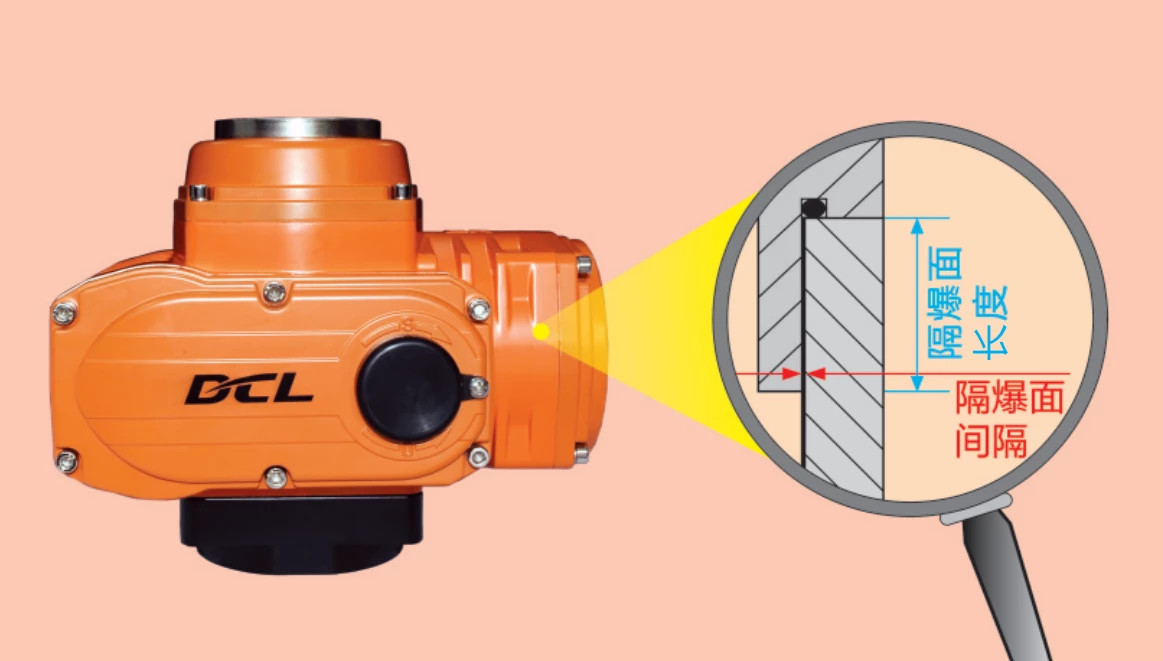

Flameproof (Exd) Design Principles

✔ Explosion may occur inside the device, but the enclosure prevents it from igniting the external environment.

✔ Flameproof joints are designed with the correct gap and length to contain internal explosions.

✔ Strong enclosures withstand high internal pressure without breaking.

DCL Explosion-Proof Components

✔ Motor compartment

✔ Electrical component compartment

✔ Wiring compartment

5. DCL Explosion-Proof Actuator Certification

Explosion Protection Level: Exd IIC T4 Gb

✔ Ex – Explosion-proof marking

✔ d – Flameproof type (“Exd”)

✔ II – Non-mining applications

✔ C – Explosion group (higher safety requirements)

✔ T4 – Maximum surface temperature 135°C

✔ Gb – Equipment protection level

Conclusion

Explosion-proof actuators are essential in hazardous environments to prevent ignition of explosive gases. DCL’s Exd IIC T4 Gb-rated actuators ensure safety by:

✔ Containing internal explosions

✔ Preventing sparks & excessive heat

✔ Withstanding high pressure without rupture

These design measures make DCL actuators reliable and safe for industrial applications in explosive atmospheres.

鄂公网安备 42018502006527号

鄂公网安备 42018502006527号