Field Bus

The cost of process control systems can be significantly reduced through fieldbuses. At the same time, the introduction of serial communication buses in process automation can drive functional innovations in control devices and electric actuators in industrial sites, because after using the bus system, continuous innovation of functions and parameters can be achieved without changing hardware facilities, which often greatly hinders innovation in process control systems. At the same time, the use of fieldbus technology can also realize factory asset management and remote parameterization. The implementation of these innovative methods can improve the efficiency of factory operations.

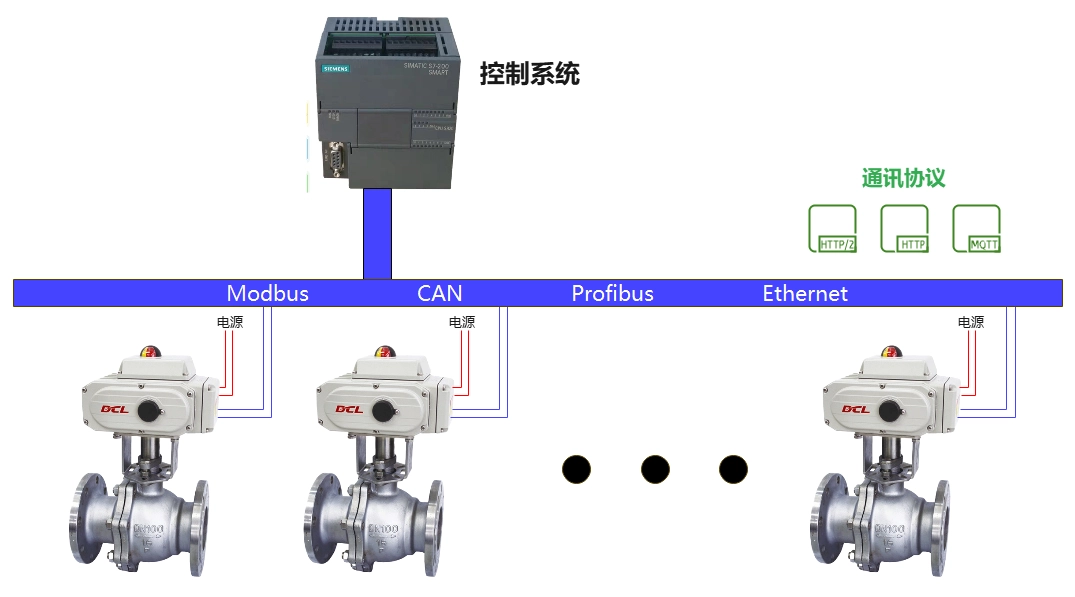

Through DCL industrial bus devices, bus functions can be upgraded for traditional non-bus electric actuators, and the upgrade costs of mechanical and electrical systems can be avoided during the upgrade process. You can also configure DCL industrial bus devices when selecting DCL electric actuators to achieve bus-based and flexible deployment of process control systems. In this way, you can continue to optimize the functions of the process control system (such as self-diagnosis, data logging, parameter optimization, firmware upgrade) after the system deployment is completed without changing the hardware.

The supported protocols are: Modbus, CAN, Profibus, DeviceNet, Foundation Fieldbus, HART, Ethernet.

鄂公网安备 42018502006527号

鄂公网安备 42018502006527号