Common Troubleshooting

Suitable for adjustable actuators

该向导适用于DCLExplosion-Proof/General Series/The adjustable actuators of the quick-opening series are available in the following models:

- General Series:DCL-05E/DCL-10E/DCL-20E/DCL-40E/DCL-60E/DCL-100E/DCL-160E/DCL-250E

- Explosion-Proof:DCL-Ex05E/DCL-Ex10E/DCL-Ex20E/DCL-Ex40E/DCL-Ex60E

1、Common malfunctions and troubleshooting methods.

| fault | Possible reasons | Exclusion method |

|---|---|---|

| The actuator will not open or close during initial startup | 1. Incorrect wiring | Check if the wiring is correct according to the wiring diagram of the actuator? |

| 2. Incorrect power supply | Confirm that the output voltage of the power supply is ± 10% of the rated voltage of the actuator, and the output current is 3 times the rated current of the actuator. | |

| 3. SA is not set to level 1 or 3 | Check and set SA to either 1st or 3rd gear. | |

| 4. Emergency stop switch disconnected (for actuators equipped with emergency stop function) | Check and turn on the emergency stop switch. | |

| 5. Input Signal exceeds the Range | Use a multimeter to measure the voltage between control modules P3 and P4, and verify if the voltage is within the following Range: | |

| 6. Set the fully open and fully closed positions to the same position. | Refer to"How to set up a regulating electric valve Calibração de viagenssection, correctly set the fully open/fully closed position. | |

| The actuator stops before running to the target position | 1. Valve stuck | Check for valve sticking, eliminate sticking, and retry after actuator overload protection cooling. |

| 2. Potential solid substances in the fluid medium can cause valve jamming. | Check if there is any solid object stuck in the valve in the fluid medium, eliminate the valve stuck, and retry after the actuator overload protection has cooled down. | |

| 3. Setting the fully open or fully closed position to the middle position is incorrect. | Refer to"How to set up a regulating electric valve Calibração de viagenssection, correctly set the fully open/fully closed position. | |

| 4. Incorrect calibration of input signal Range. | Refer to"How to set up a regulating electric valve Input Signal calibrationsection, correctly calibrate the input signal Range. | |

| Using the handle, the actuator cannot be rotated | Potential solid substances in the fluid medium can cause valve jamming. | Check if there is any solid object stuck in the valve in the fluid medium, eliminate the valve stuck, and retry after the actuator overload protection has cooled down. |

| 2. Valve stuck | Check for valve sticking, eliminate sticking, and retry after actuator overload protection cooling. | |

| 3. The actuator deceleration mechanism is damaged. | Remove the actuator from the valve and turn the handle. If it cannot rotate, replace it with a new actuator. | |

| The feedback signal is incorrect | 1. Open circuit of the circuit | Measure the voltage between control modules P5 and P6 with a multimeter. If the measured value is>18V, it indicates an open circuit signal. Check and repair any wiring issues. |

| 2. The input impedance of the feedback signal receiving end is too high. | Measure and confirm that the input impedance of the feedback signal receiving end is less than 800 ohms | |

| 3. Feedback signal calibration error. | 1. Refer to the"How to set up a regulating electric valve"Calibração da corrente de saídasection to calibrate the output Signal. |

2、Please check that the application conditions are in accordance with the parameters.

Electric actuators can fail due to improper use or under the wrong application conditions. Long-term trouble-free operation of the actuator will be ensured under the application conditions defined in the product specification.

- Supply voltage:The voltage of the power supply must be within the rated operating voltage of the actuator. Overvoltage or undervoltage may result in reduced actuator life.

- Supply current:Since the starting current of the motor is much larger than the rated current. To ensure reliable operation of the actuator, use a power supply with an output current capacity more than three times the rated current of the actuator.

- Temperature:Ensure that the actuator operates within the rated operating temperature range. Use of the actuator in environments outside of the rated operating temperature range may result in malfunction or reduced service life of the actuator, and ultimately, failure of the actuator.

- Environment:DCL开关型执行机构具有IP67防风雨等级。一般适用于室内或室外应用。提供一定程度的防雨、防溅水。保护执行器免受雨淋,雪、冰和紫外线(阳光)Typically extends the life of the product. Very corrosive environments may cause premature failure of electronic equipment. Do not use non-explosion-proof series actuators in explosion-proof environments.

- Energized persistence rate:DCL开关型执行器的通电持续率为70%(每分钟运行42秒,必须关闭18秒),超过70%of the energization duration rate will cause the motor to go into overheat protection.

3、Check that the actuator is wired correctly

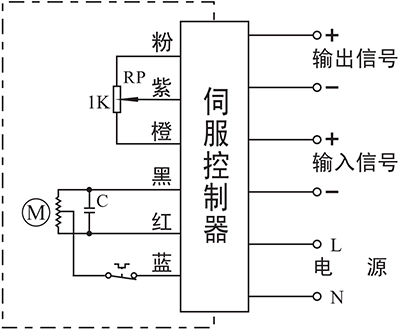

E型:带伺服控制器(调节型)

输入:4~20mA / 0~10V Arbitrary Configuration.

输出:4~20mA / 0~10V Arbitrary Configuration.

总线:Modbus / CAN

物联网:WIFI/LoRA/4G DTU

Wiring Instructions:

1、 “电源”输入端的“N”接中线,“L”接 相线;

2、 “输入信号”端的接输入信号的负 极,“+”接输入信号的正极;

3、 “输出信号”端的接直流电流表的 负极,”+”Connect to the positive terminal of the DC ammeter.

FType: with position transmitter

通过开关电路实现“开”、“关”operation, and outputs a set of fully open and fully closed active signals.

Wiring Instructions:

1、 “电源”输入端的“N”接中线,“L”接相线;

2、 “电源”输入端的相线“L”接“关”时,向关方向运行,接“开”时,向开方向运行;

3、 “输出信号”端的接直流电流表的负极, “+”Connect to the positive terminal of the DC ammeter.