An electric actuator utilizes a motor-driven reduction mechanism to achieve both rotary and linear motion of a valve. Since it is powered by a motor, the electric actuator features a simple and reliable structure without requiring additional support systems like pneumatic or hydraulic sources. This results in higher energy efficiency and lower operational costs. At the same time, it offers greater reliability and a longer service life. By incorporating an electronic control module, the electric actuator enables precise, rapid, and complex valve movements. As a result, it is ideal for fluid control applications requiring higher precision, faster response, and greater efficiency.

Pålitelig og slitesterk

Electric actuators feature a simple structure, making them more reliable and durable. As a non-contact motion device, an electric motor experiences significantly less mechanical wear compared to cylinders, which rely on mechanical friction for movement. Additionally, motors do not require airtight sealing, making them more tolerant of mechanical wear. Under the same level of wear, a motor can continue to operate normally, whereas a cylinder may completely fail due to air leakage. Therefore, electric actuators offer greater reliability and durability, making them suitable for a wider range of applications.

Kompakt og plassbesparende

Electric actuators feature a simple structure with a compact and space-saving design. In fluid control systems for ships, vehicles, trains, and aviation, installation space is often limited. As a result, electric actuators with a compact and efficient design are the preferred choice for such applications.

Høy effektivitet

Electric actuators are highly efficient, saving over 60% of energy. Higher efficiency translates to lower costs and reduced carbon emissions. Unlike pneumatic actuators, electric actuators do not require an air supply, which alone accounts for more than 60% in energy savings. This is because air compressors operate at only about 30% efficiency, whereas low-power electricity transmission approaches nearly 100% efficiency. Additionally, when factoring in air leaks and the wasted pressure released into the environment by pneumatic systems, electric actuators provide even greater energy savings.

Høy presisjon og kontrollerbarhet

Electric actuators offer superior controllability and high precision. Through a control module, motor movement parameters—such as speed and output torque—can be precisely adjusted. In specific fluid control applications, electric actuators can also achieve advanced functions such as soft start, variable speed control, constant torque output, and anti-surge protection, ensuring optimal performance and adaptability.

Brukervennlighet

Electric actuators are user-friendly and widely applicable, making them suitable for nearly all fluid control circuits except for ultra-large diameter systems. Simply connecting the local power supply to the actuator allows it to drive the valve and regulate fluid flow. Unlike pneumatic or hydraulic actuators, electric actuators do not require additional infrastructure such as air or hydraulic sources, eliminating the need for complex pipeline installations. Additionally, maintaining an electrical power supply is far simpler than maintaining pneumatic or hydraulic systems, further enhancing ease of use.

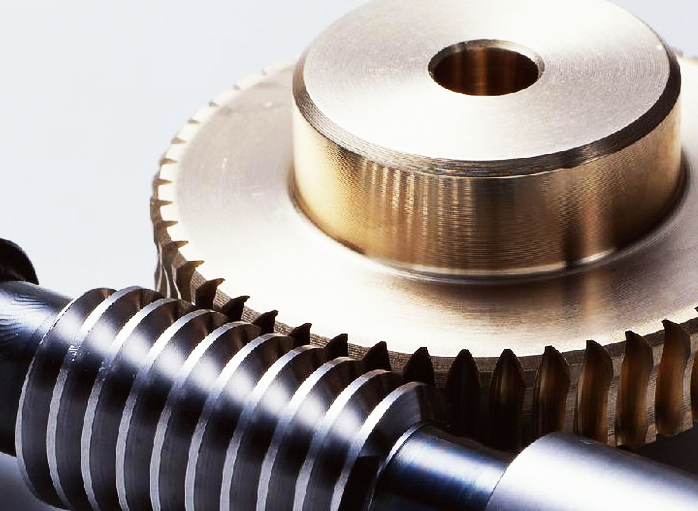

DCL elektrisk aktuator

The DCL electric actuator is designed with a strong focus on reliability and durability. With features such as ultra-durable gear profiles, wide-frequency anti-interference capabilities, and a fully encapsulated control unit, DCL actuators are widely used in harsh operating conditions. They have proven their reliability in environments with extreme electromagnetic interference, such as base stations, ultra-high voltage facilities, and radiation-intensive areas. Additionally, they perform exceptionally well in challenging environmental conditions, including offshore, high-humidity, salt fog, dust, and extreme temperature variations.

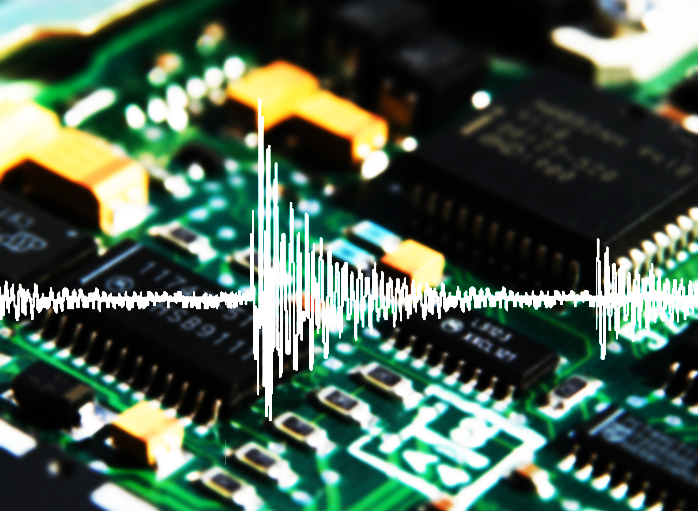

By integrating with DCL Control’s Industrial IoT system, DCL electric actuators can also enable wide-area fluid control, self-diagnosis, lifespan prediction, and proactive maintenance. These advanced features help prevent unexpected downtime in critical fluid control processes, minimizing disruptions and financial losses.

鄂公网安备 42018502006527号

鄂公网安备 42018502006527号