About Explosion Protection

What's the explosion?

A prerequisite for an explosion is that the explosive substance must be mixed to a certain extent with oxygen to cause a chemical reaction under suitable ignition conditions. If the reaction speed exceeds the speed of sound, it is defined as an explosion.

An explosive mixture that has accumulated to a certain level suddenly explodes and causes a destructive effect in the form of a blast wave.

What is explosion-proof?

Explosions can be prevented by limiting the occurrence of any of these three conditions. In many applications, the presence of explosive substances and oxygen is unavoidable, so the source of ignition must be limited.

Electrical equipment is a potential source of ignition, resulting in increased surface temperatures during operation, electrostatic discharge, or sparks caused by an instantaneous electric current.

Explosion-proof electrical equipment is designed to avoid high surface temperatures and sparks during operation. As a result, explosion-proof electrical equipment does not become a potential source of ignition.

Classification of potentially explosive environments

Generally electrical equipment for explosive atmospheres can be divided into two categories.

I类煤矿用电气设备;

IIClasses of electrical equipment for use in explosive atmospheres other than coal mines.

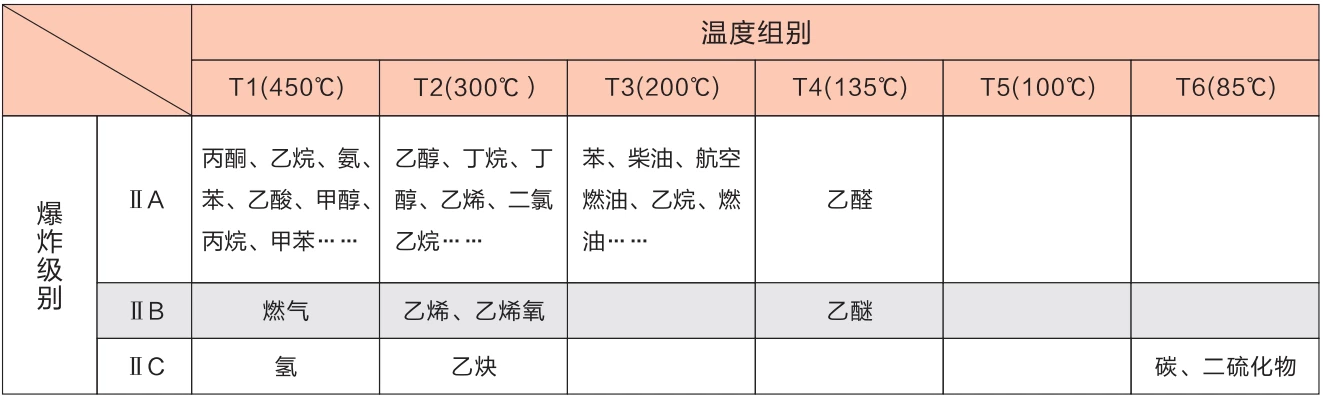

对于II类电气设备,按照爆炸性气体的最大试验安全间隙(隔爆型)和最小试验引燃电流(本安型)Can be divided into three explosion levels IIA, IIB, IIC, and IIB class equipment can be applied to the conditions of use of IIA equipment, IIC class equipment can be applied to the conditions of use of IIA and IIB equipment.

对于II类电气设备,按照允许的最高表面温度可分为T1(450℃)、T2(300℃)、T3(200℃)、T4(135℃)、T5(100℃)、 T6(85℃)There are six temperature groups, and the equipment in the higher temperature group can be applied to the operating conditions in the lower temperature group.

90%The above explosive gases are included in the explosion classes II A, II B and the temperature groups T1 ~ T4.

How is explosion-proofing achieved?

There are different ways to make electrical equipment suitable for explosive environments, which are described in detail in standards such as GB3836, IEC60079 and EN50014.

DCLExplosion-proof Series电动执行机构按防爆类型为“隔爆型”(Exd)的型式制造,符合GB3836.1-2010、GB3836.2-2010、EN/IEC 60079-0s EN/IEC 60079-1、EN/IEC 60079-31 s EN ISO/IEC 80079-36、EN ISO/IEC 80079-37Standard Requirements.

隔爆型(Exd)

Explosion-proof actuators allow for explosions inside the device. The explosion-proof surfaces of the housings are designed to prevent internal sparks or explosive carriers from coming into contact with the outside world, which is ensured by a suitable clearance of the surfaces and a sufficiently large length of the surfaces. At the same time, a robust casing can withstand the high pressures generated by an internal explosion without being damaged.

DCLExplosion-proof SeriesThe following components of the actuator are designed and manufactured according to the explosion-proof standard:

♦电机腔 ♦电气元件腔 ♦wiring compartment

Explosion-proof grade

DCLExplosion-proof SeriesThe Explosion-proof grade of the electric actuator is:

ExdllCT4Gb

Ex-Explosion-proof marking

d-防爆类型,表示为”隔爆型”;

U—设备类别,表示除煤矿外的其它爆炸性气体环境用电气设备;

C-爆炸级别,该级别决定执行机构各隔爆接合面的尺寸(长度和间隙);

T4一温度组别,表示允许执行机构最高表面温度为135℃.

Gb-Indicates the level of device protection.

鄂公网安备 42018502006527号

鄂公网安备 42018502006527号