Using IoT to Monitor and Analyze Intermittent Actuator Failures

Customer Feedback: The Three-Way Valve in the Cooling System Failed to Reach the Designated Position

A nuclear power customer reported an intermittent failure of the actuator. Specifically, after the control system issued an opening command via a 4-20mA signal, the actuator’s feedback position remained unchanged. Upon cutting off the power and inspecting the site, the mechanical position indicator on the actuator showed no movement.

Special Application Scenario

Due to strict safety protocols in this application, power must be cut off before personnel can enter the site, making it impossible to preserve the fault status.

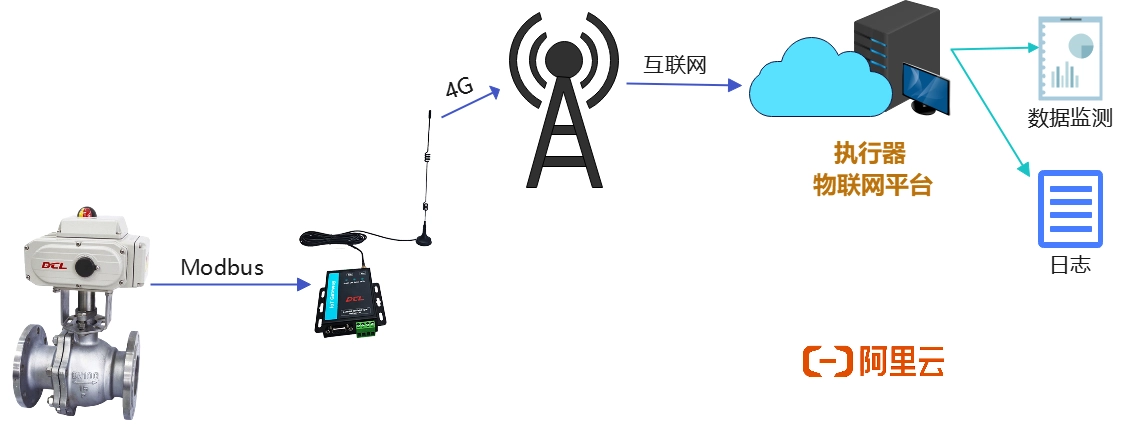

Deploying DCL IIoT to Monitor Actuator Data

By deploying the DCL IIoT (Industrial Internet of Things) diagnostic system, the actuator’s operational data was continuously monitored for over a month. When the failure reoccurred, analysis of the data within the fault window revealed that the actuator received an opening signal of 0.1mA, triggering an input signal fault.

Problems solved

After analyzing the wiring between the control system and the actuator, the customer successfully located and resolved the issue. After more than three months of continuous monitoring, the problem did not occur again, and the on-site issue was fully resolved.

鄂公网安备 42018502006527号

鄂公网安备 42018502006527号